ROBODRILL CNC and Servo Maintenance

COURSE DESCRIPTION

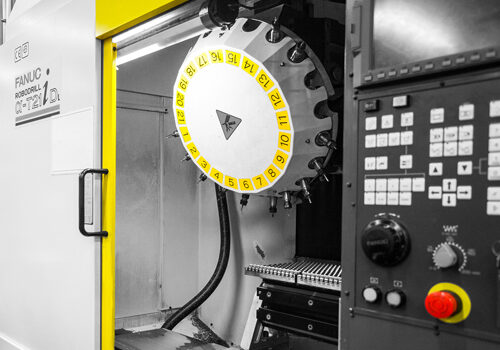

This 3 day course covers maintenance of FANUC ROBODRILL, navigation of screens, overview of the control system and servo/spindle units. Participants should have basic maintenance experience.

SUBJECTS COVERED

PPM topic/schedule, including fans, battery and filter replacement

ROBODRILL screens, features and functions

Tool change, maintenance and recovery

Axis removal and replacement

Spindle & spindle motor replacement (explanation)

CNC

Hardware configuration

Connections

Screen navigation for maintenance, smart trouble shooting

PMC diagnostics

Common alarms

Data Backup

FANUC I/O link I

Servo / spindle

Hardware overview

Connections including FSSB

Servo/spindle screens

Common alarms

Hardware replacement

Troubleshooting