Advanced (Mechanical) Maintenance

COURSE DESCRIPTION

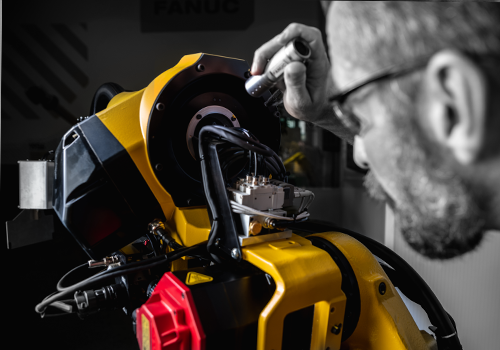

This course is designed for maintenance personnel who are responsible for maintaining the robot and controller. The course covers mechanical troubleshooting of the robot and controller. In addition to presentations and demonstrations, the course offers a series of lab exercises for the student to complete. Lab exercises relate directly to the classroom presentation and are intended to reinforce what the student has learned through hands-on activities. Recommended safety procedures are integrated into all training exercises.

COURSE OBJECTIVES

Upon completion of this training course the student will be able to:

Understand the basic robot movements

Disassemble and reassemble a FANUC robot

Disassemble and reassemble a FANUC controller

Test the robot characteristics with basic programs

Resolve common faults

Proceed to regular preventative maintenance

Be familiar with FANUC telephone support requirements and procedures

SUBJECTS COVERED

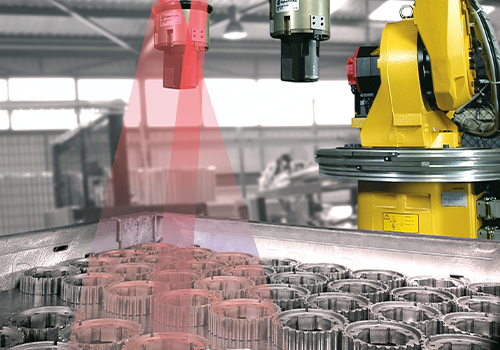

Robot general characteristics

Robot safety and awareness

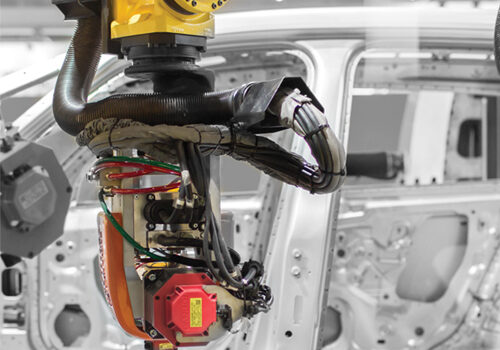

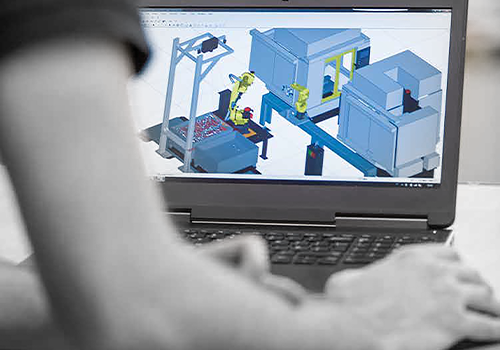

Robot, controller and operator panel description

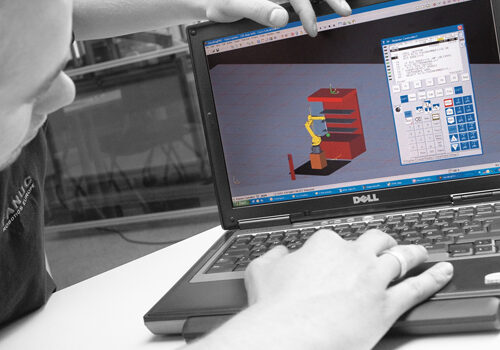

Basic program creation

Backing up procedures

Removal/strip down and replacement of controller modules –amp/CPU/power supply/e-stop unit etc.

Removal/strip down and replacement of mechanical unit –motors, pulse coders, internal gears etc.

Use of FANUC manuals/connection diagrams

Recovering software from backups/images

Resolving faults associated to include mastering

Preventative maintenance procedures and schedules

Greasing procedures and techniques